Unit 1301-2, No. 365, Chengyi Street, Software Park Phase Iii, Xiamen, Fujian, China +8618250168507 manager@xmstrongtech.com +8618250168507 Xiamen Strongtech Co., Ltd.

Unit 1301-2, No. 365, Chengyi Street, Software Park Phase Iii, Xiamen, Fujian, China +8618250168507 manager@xmstrongtech.com +8618250168507 Xiamen Strongtech Co., Ltd.

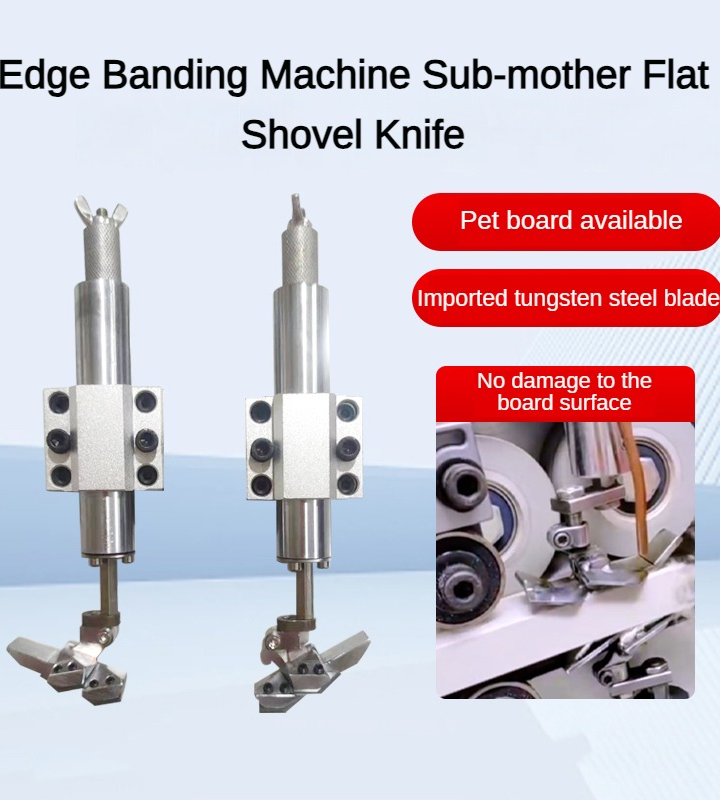

STR has a goal to supply the customers with superior parts of edge banding machine with ordered advanced and high quality manufacturing processes output and exuded throughout every detail. A Premium materials selection as well as a quality assurance test. This is done to ensure that every part used in the edge banding machines is made with precision and enhances work efficiency. And these parts of edge banding machine are designed and manufactured to be self explanatory even to other types of edge banding machine increasing the efficiency of the machines, extending their life and providing stable support of the woodworking process.

STR edge bander incorporates rugged and dependable industrial components. All the details can take the batting of any woodworking workshop because the materials and production quality are top-notch. The strength of the STR parts enhances the durability of the edge banding machines ensuring lower downtimes associated with maintenance and repair. This normally cut costs in the running of the businesses after some time, but also guarantees the efficiency of the machines over a longer duration. For woodworking professionals, by choosing STR parts, they do not have to worry about the safety of their investment and the machines will operate efficiently as always.

STR edge bander parts come with compatibility features, parts manufacturers. Be it a new model or an old model, STR parts are understood to design for numerous edge banding machines hence their use is emphasized in businesses of every type. This compatibility increases the longevity of the existing machines as it allows simple upgrades in parts rather than purchasing new machines completely. The STR brand appreciates the value of versatility in the woodwork industry, and true to this perspective, their parts do not ignore the diverse requirements of their customers.

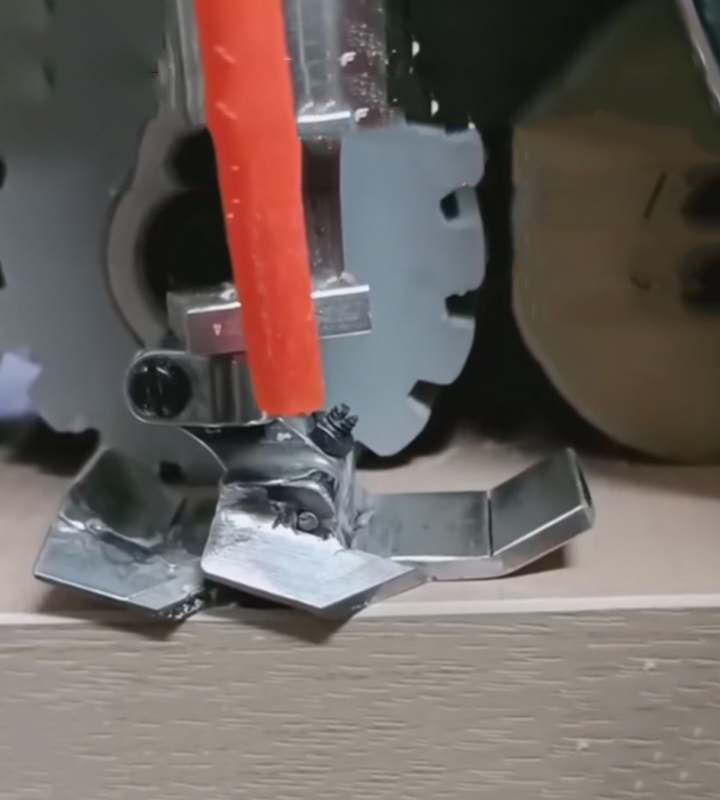

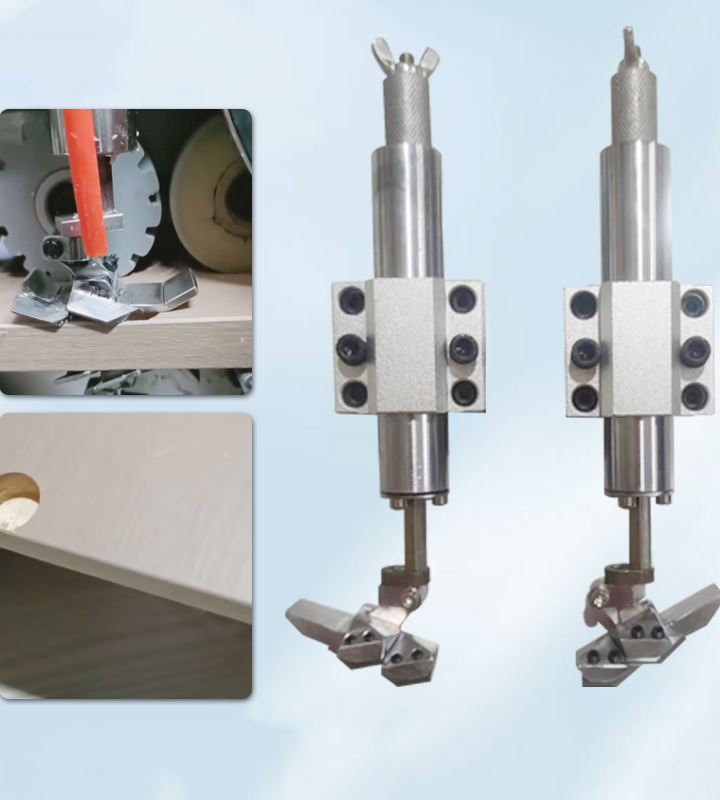

Since STR edge bander parts are heavily dependent on accuracy, each part is manufactured to exacting standards as demanded by the edge banding machines used to ensure the edges of wooden panels are properly done. STR parts can be used on thin veneers or thick melamine and maintains the same quality control regardless of the material. This detail is what makes STR unique, moreover, it increases the quality of the finished product’s look. Any professional working with edge banding machines will appreciate the fact that their craft will be up to standard thanks to STR parts.

In the current climate of global warming, it is crucial that operations utilize green manufacturing techniques. STR edge bander parts are some of the most advanced environmentally conscious products for woodwork. These technological components are designed to reduce material wastage and energy resources used up in the processes. The cutting lost in STR parts production is less, and hence their contributions to waste from offcuts are low. In addition, these replacements are of a strong build, hence less frequent changes means less equipment manufacturing pollution. Using STR edge bander parts, companies are able to continue enjoying cutting edge technology while being able to support ecological conservation.

Xiamen Strongtech Co., Ltd., based in Xiamen, China, specializes in woodworking machinery R&D, manufacturing, marketing, and services. Committed to offering safe, reliable, efficient, energy-saving, and cost-effective equipment, their product range includes various saws, planers, sanders, CNC routers, and woodworking tools. With expertise from Taiwan, Japan, and Germany, their "STR" and "LIVTER" brands enjoy a broad customer base across North America, Eastern Europe, Southeast Asia, East Asia, Western Europe, and Northern Europe. They aim for mutual development and success through win-win cooperation with global clients.

Precision cutting with high efficiency for bulk orders.

Consistent quality output for large-scale woodworking projects.

Advanced technology for precise, high-volume production.

Robust and reliable for superior finishing in furniture manufacturing.

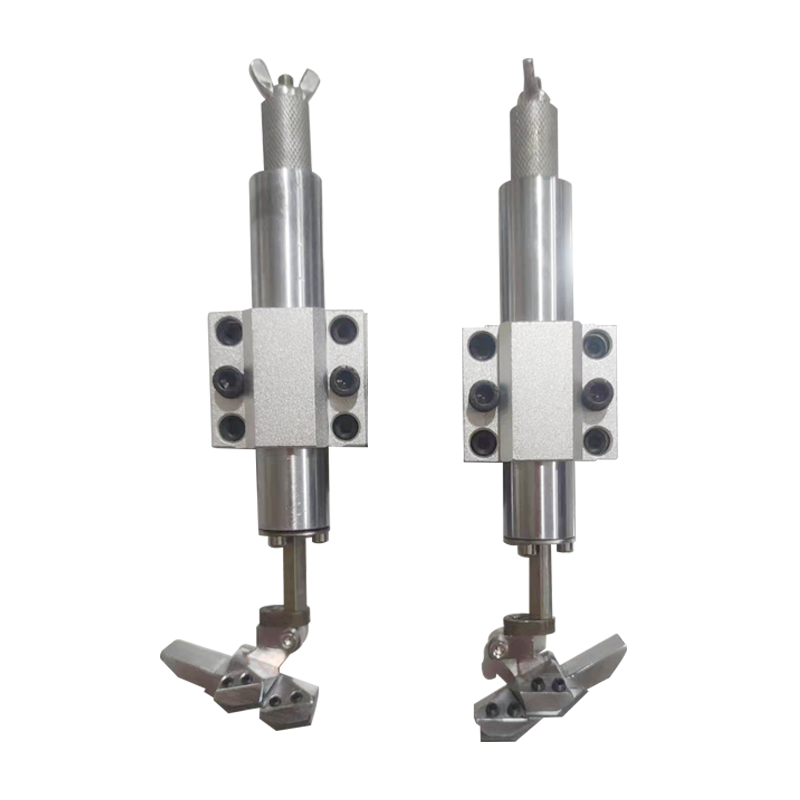

Our edge banding machine parts are crafted from high-grade materials such as stainless steel, aluminum, and specialized engineering plastics, ensuring durability and resistance to wear.

Yes, STR parts are designed to be versatile and can fit a wide range of edge banding machines from various manufacturers, facilitating easy integration and replacement.

We provide detailed product specifications and compatibility information on our website. Additionally, our customer service team is available to assist you in identifying the right part for your machine.

Lead times may vary depending on the part and current demand. Generally, most parts are shipped within 2-5 business days after the order is placed, with delivery times contingent upon the shipping method selected.

STR stands behind the quality of our products. We offer a limited warranty on our edge banding machine parts, covering defects in material and workmanship under normal use conditions. Specific warranty terms are available upon request.