When it comes to the woodworking processes, precision and efficiency are undoubtedly the main factors. This is how the beam saw machine, one of the finest contemporary pieces of equipment, is meant to be understood. The perspective of the concluding article will be concerned with the notjn rwn tbs parts pxwpms wdsa ts so working beam saw firmly entrenched in the toolkit, sr onvw rc svm involving wood machining.

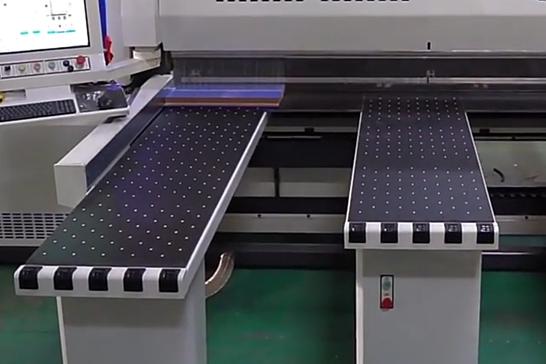

The beam saw machine is a state-of-the-art cutting instrument suitable for cutting large volumes of wood in hardcore building projects. Its solid build coupled with sophisticated cutting techniques makes sure that, if one cuts through wood today, then they will cut tomorrow, and every other time with the same accuracy, and so it is for those who aim when crafting objects.

The one of such interesting possibilities of this particular beam saw machine is its universality in terms of the materials it operates with. The machine can work with hardwood, softwood, or even engineered wood products using its sharp blade to make well-structured cuts. This universal feature is particularly important for those businesses where there is a need to purchase one machine that can perform several functions at the same time, because there is no need to buy individual machines for different purposes.

The user-friendly interface of the beam saw machine’s operation hints at another advantage of the machine. With little effort, the operators can easily program the machine to perform complicated cuts within no time. This programming logic minimizes the time taken on induction and reduces the machine turn around time which is very beneficial giving the current state of manufacturing industries.

Due importance has also been given to the safety concern regarding the beam saw machine. Protective measures such as blade guards and emergency stop buttons, to name a few, are few of the advanced safety measures which have been installed to protect the operators. These are particularly critical in high-speed cutting operations as attention is demanded all through.

Additionally, there is a further dust extraction system which improves the efficiency of the beam saw machine. This system helps in controlling airborne dust and other particles created from the cutting action that is harmful to one’s health and also keeps the working area productive.

To sum up, it can be concluded that the beam saw machine can be characterized as a revolution in the field of precise cutting. For woodworkers, the ability to combine advanced cutting technologies, operational ergonomics, comprehensive safety elements, and dust extraction, is such a powerful machine. As the developments within the sector take root, the beam saw machine will not be left behind instead it will help the artisans and the manufacturers to reach or exceed the required standards.

EN

EN

AR

AR

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

PT

PT

RU

RU

ES

ES

TR

TR