The role and importance of wood scanners

The wood scanner machine uses high-precision scanning technology to detect the internal and external structure of wood in real time, thereby ensuring that each piece of wood meets the predetermined quality standards. The main functions of the wood scanner machine include detecting the density, moisture, texture, defects, etc. of wood, and can provide data support in all links of the production process. Through precise scanning, the wood scanner machine can effectively identify cracks, scars, rot and other problems in the wood, avoiding these problems from affecting subsequent processing.

In the woodworking production process, the quality of wood directly determines the quality of the final product. The application of the wood scanner machine enables woodworking companies to conduct quality inspections when wood is put into storage, thereby avoiding the flow of inferior wood into the production line.

The key to ensuring the consistency of woodworking products

In addition to ensuring the quality of wood, the wood scanner machine can also ensure consistency in woodworking production. In woodworking production, consistency refers to the uniformity of each piece of wood in terms of size, texture, color, etc., especially for mass-produced woodworking products, consistency is particularly important. By accurately scanning each piece of wood, the wood scanner machine can monitor the various parameters of each piece of wood in real time, and adjust the production process according to the data to ensure the consistency of the product's size and appearance.

For example, when manufacturing wood products such as furniture, flooring, doors and windows, consistency is essential to enhance the aesthetics and functionality of the product. The wood scanner machine can evaluate each piece of wood through real-time detection and data analysis, and make appropriate treatments and corrections, so that each finished product meets the expected quality standards.

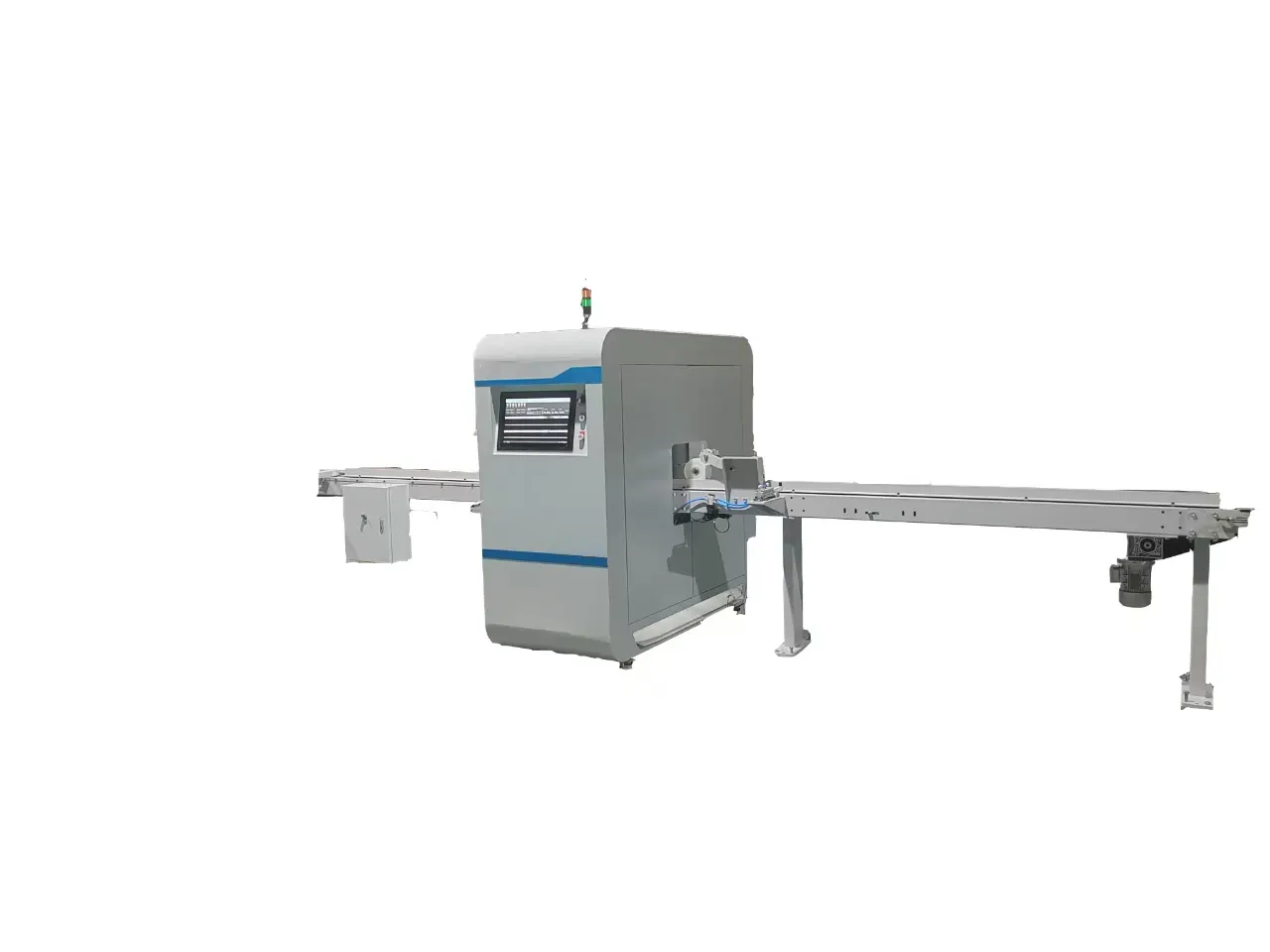

STR wood scanner machine: Providing intelligent solutions for woodworking production

In the woodworking industry, the STR brand wood scanner machine has been widely recognized for its advanced technology and efficient performance. Our wood scanner machine uses the latest scanning technology and algorithms to accurately detect various defects and properties of wood. Through powerful data analysis capabilities, our STR wood scanner machine can provide real-time feedback and reports to help woodworking companies detect wood problems in a timely manner and make corresponding adjustments, thereby ensuring the smooth operation of the production line.

STR's advantages and market prospects

As a leading brand in the field of wood scanner machines, STR has won the trust of global customers with its technological advantages and high-quality products. Our products are not only suitable for large-scale industrial production, but also meet customized needs and provide flexible solutions. As the woodworking industry's demand for intelligence and efficiency continues to increase, our wood scanner machine will continue to promote innovation and development in the industry and provide more efficient and accurate wood quality inspection solutions for global woodworking companies.