Introduction

In the world of mechanical engineering and automotive maintenance, the Crankshaft Polishing Machine plays a crucial role in ensuring the smooth operation and longevity of engines. This detailed description will explore its features, working principles, and benefits.

Features of the Crankshaft Polishing Machine

- Advanced Polishing Technology

The Crankshaft Polishing Machine is equipped with state-of-the-art polishing mechanisms. It uses high-quality abrasives and a precise rotational system to achieve a smooth and even finish on the crankshaft. The machine can adjust the polishing intensity and speed according to the material and condition of the crankshaft, ensuring optimal results every time.

- Precision Control System

With a sophisticated control system, operators have precise control over the polishing process. They can set parameters such as the pressure applied, the rotation speed of the crankshaft, and the duration of the polishing cycle. This level of control allows for customized polishing to meet the specific requirements of different engines and applications.

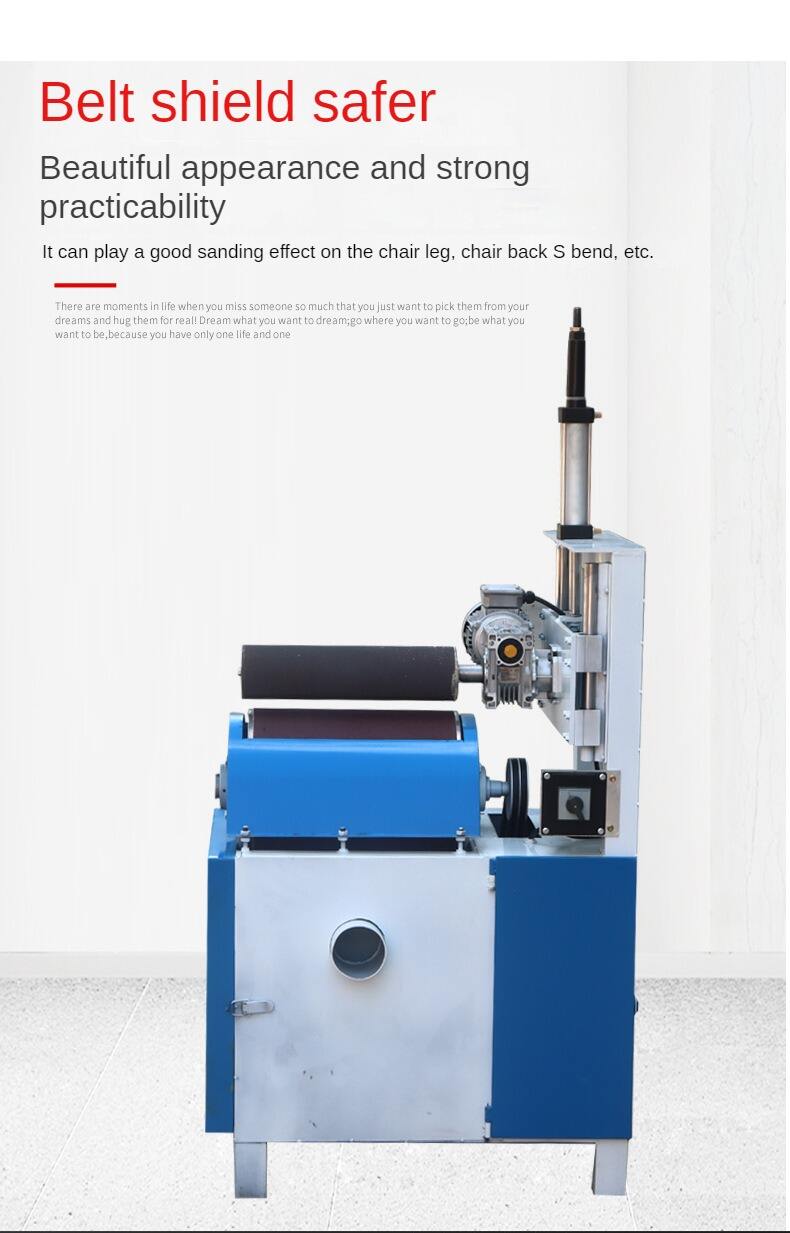

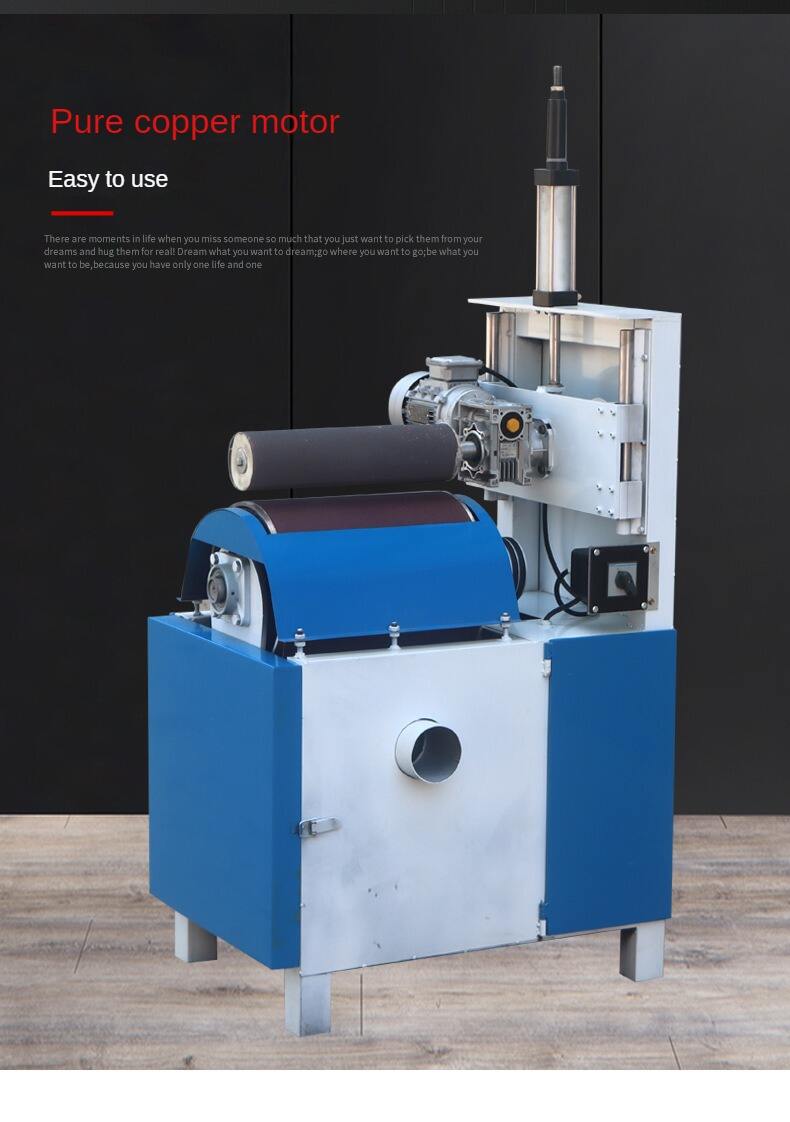

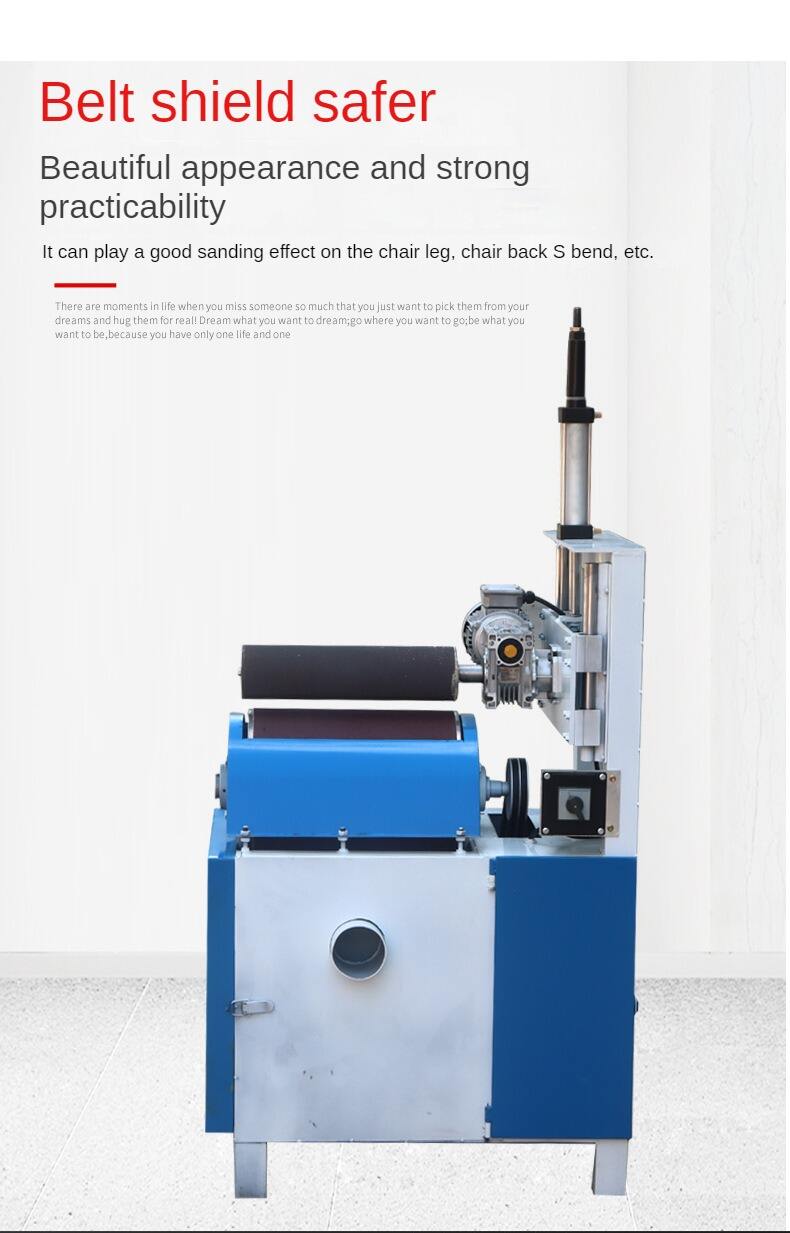

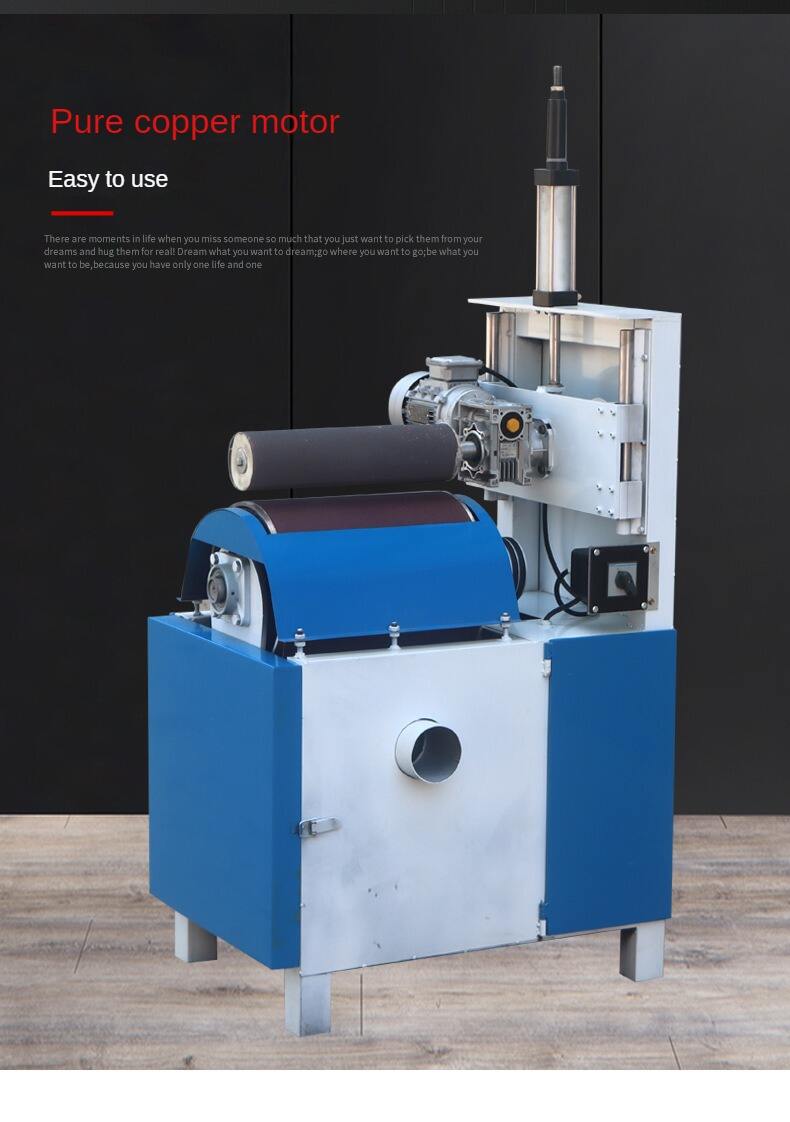

- Durable Construction

Built to last, the machine has a sturdy and durable frame. It is made of high-quality materials that can withstand the rigors of continuous use in an industrial environment. The components are designed for long-term reliability, reducing the need for frequent maintenance and replacement.

Working Principles of the Crankshaft Polishing Machine

- Rotational Polishing Action

The crankshaft is mounted on the machine and rotated at a controlled speed. As it rotates, the polishing tools come into contact with the surface of the crankshaft, gradually removing any imperfections and smoothing the surface. The rotation speed and pressure are carefully calibrated to ensure a uniform finish across the entire length of the crankshaft.

- Abrasive Material Interaction

The abrasive materials used in the machine are selected based on the hardness and characteristics of the crankshaft material. They work by gently grinding away the rough spots and creating a smooth, polished surface. The abrasives are constantly replenished or adjusted to maintain their effectiveness throughout the polishing process.

- Quality Assurance Monitoring

During the polishing operation, the machine may be equipped with sensors and monitoring systems to ensure the quality of the finish. These systems can detect any irregularities or deviations from the desired surface smoothness and prompt the operator to make adjustments if necessary.

Benefits of Using the Crankshaft Polishing Machine

- Enhanced Engine Performance

A smoothly polished crankshaft reduces friction and wear within the engine. This leads to improved power output, better fuel efficiency, and smoother operation. It also extends the life of the engine components, reducing the frequency of costly repairs and replacements.

- Precision Engineering for Optimal Fit

The precise polishing achieved by the machine ensures that the crankshaft fits perfectly with other engine components, such as bearings and pistons. This optimal fit reduces vibrations and noise, further improving the overall performance and reliability of the engine.

- Cost-Effective Solution in the Long Run

While the initial investment in a Crankshaft Polishing Machine may be significant, the long-term benefits in terms of reduced maintenance costs and improved engine performance make it a cost-effective choice. It allows businesses and mechanics to provide high-quality engine services, enhancing their reputation and competitiveness in the market.

In conclusion, the Crankshaft Polishing Machine is an essential tool for anyone involved in engine repair, maintenance, or manufacturing. Its advanced features, precise control, and durable construction make it capable of delivering outstanding results. By using this machine, professionals can ensure the optimal performance and longevity of engines, contributing to a more efficient and reliable mechanical world. Whether in the automotive industry or other fields that rely on engines, the Crankshaft Polishing Machine is a valuable asset that unlocks the potential for precision engineering and enhanced performance. So, invest in this remarkable machine and experience the difference it can make in your engine-related operations.